Run your entire brewery from one connected system — from brewing and fermentation to packaging, excise and sales.

Our Brewery ERP is a purpose-built platform that helps connect and simplify every aspect of your brewing process. It helps you manage recipes, monitor production, control costs and stay audit-ready—with one source of truth for every batch.

Batch & Recipe Management

Cost of Goods (COGS) per Bottle

Keg & Container Tracking

Quality Control

Compliance Monitoring

Real-Time Production Insights

Reporting

Running a brewery is more than just brewing great beer — it’s about maintaining consistency, control and compliance.

Too many spreadsheets are the cause of data gaps between the processes of brewing, packaging and sales. Our Brewery ERP organizes all these processes under one roof for seamless visibility and control.

Manual filing of excise can cause costly delays and errors. We will automate all those duty calculations and excise reporting with our ERP, keeping you compliant effortlessly.

Every item/ingredient is traceable from grain to glass, enforcing accountability and quality in your operations.

Our ERP connects directly to your shop floor, pulling live brewing and fermentation data into one real-time dashboard.

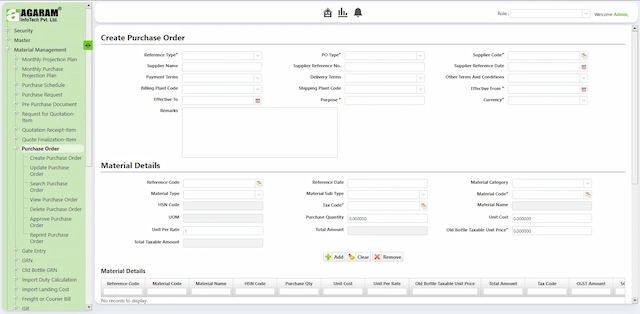

Our Brewery Management System integrates the art and science of brewing into

a single, intelligent platform.

Every process,

from the procurement of raw materials to the final dispatch, is linked, monitored

and optimized for effectiveness, quality and compliance

Streamlined material flow and total visibility across your brewery.

Every stage of your brewing operation– from grain to glass– is automated and synchronized.

Forecast needs and prevent stockouts.

Track recipes, pressure, and temperature in real time.

Get instant alerts for deviations.

Monitors temperature, pressure, flow and carbonation end-to-end.

Ensure timely replenishment and avoid stock-outs.

Automate labeling, inventory, and traceability.

Generate compliant reports and dispatch faster.

Access real-time dashboards for production and sales.

Our Brewery ERP easily adjusts to your size and brewing technique, providing

control, consistency and efficiency at

every stage, whether you're using a boutique setup or a

large-scale

regional operation.

Every drop you brew is traceable — from the first ingredient to bottle

Generate statutory reports in a click.

Keep every batch, permit and invoice stored securely.

Track any keg, batch, or bottle in seconds.

Always be ready for inspections, with zero stress.

Enjoy faster batch-to-bottle cycles, more precise inventory control and improved accuracy throughout all processes, allowing your team to spend more time brewing and less time managing.

faster batch-to-bottle turn around

More accurate material planning

Enhanced production traceability

Fewer stock deviations

Peace of mind about excise reporting

Improved product consistency

We take care of everything — from the first discussion to a successful go-live. Our experts work closely with your team to make implementation smooth, quick and reliable.

We understand your setup before we start.

Real-time testing to fine-tune performance.

Clean migration with zero disruption.

Your people get hands-on, practical training.

On-site and remote support, system reviews and continuous updates.